When it comes to secure, high-speed data, Edge (or far-edge) and microdata centers offer a smaller, leaner, and more powerful connection. A critical element of these centers is maintaining absolute data integrity, with a consistent power source to complete processing and storing data even if there were to be a power failure. In an Open Compute Project guest blog, we examine the benefits of choosing Li-ion battery backup solutions over lead-acid, such as longer life, greater energy density, and overall lower operating expenses.

One of the realities of being in business today is that demand for fast, reliable data isn’t letting up anytime soon. Whether the industry is manufacturing, telecom, retail, healthcare or finance, system engineers have found a solution by designing smaller, leaner, more powerful and localized IT (Information Technology) systems. These next-generation solutions are known by the terminology of edge, far-edge and microdata centers.

Edge (and far-edge) systems are small-scale IT processing systems (which incorporate network switching, data processing and data storage) located closer to the sites where smart devices are in use and critical data is captured. With a compact, but high-powered IT system nearby, users gain the advantage of a more secure, faster connection with less latency compared to this workload being performed at a distant mega datacenter. Between now and 2025, edge systems are expected to gain widespread adoption, processing up to 75% of all enterprise data, compared to only 10% today, according to IBM.

Edge systems such as the Open Compute Foundation’s (OCP) openEDGE are representative of ecosystems being developed and deployed in 5G buildouts, Industry 4.0 applications, and a wide variety of IoT solutions.

Much like edge systems, micro-datacenters may employ architectures closer to those of a hyperscale datacenter, yet in a significantly smaller footprint. These intermediary IT systems offer a swift, safe solution that connects edge machines and devices to a nearby source for medium-latency data processing or for archival or content delivery applications. Rather than building a massive facility surrounded by fencing in a distant rural area with a long-haul connection, a microdata-center might occupy a floor of a nearby office building or reside in a local Telco network office.

Image Source: Nokia AirFrame Open Edge Server

Image Source: Nokia AirFrame Open Edge Server

Battery backup solutions for edge systems

While the advantages of microdata and edge systems are clear, maintaining consistency in their power sources can create a bit of a challenge. A little known, but critical element of any datacenter is that of absolute data integrity. This means that system power must be available to complete processing and storing even if there is a power failure. There are typically multiple layers of backup power available in a datacenter IT system as follows:

-

-

- Backup for Volatile Memory (DRAM) <= 30 seconds

- Backup for Data Storage Devices – Hard Disk <= 90-120 seconds

- UPS (Uninterruptible Power Supply) – Chassis Level <= 5-7 Minutes

- Backup Generators – Entire datacenter > 5 minutes

-

The majority of UPS backup systems rely on lead-acid battery chemistry, however, Li-ion battery types are now common in supporting the shorter run times needed for memory and data storage applications. The main advantage of the lead-acid is low unit cost and wide availability. The Li-ion type however offers significantly better energy density (much smaller footprint), longer life, and minimal maintenance. While a traditional lead-acid battery backup unit (BBU) has lower upfront cost than a Li-ion battery solution, the savings disappear and are eventually eclipsed by the lead-acid’s need for more maintenance and shorter calendar life. It is a classic CapEX vs. OpEx analysis – where the total cost of operation (TCO) must be considered.

A system BBU does provide a critical fail-safe to prevent crippling downtime. But here’s where reliance on a lead-acid battery system can work against you in an edge computing or microdata context.

A hyperscale data center, where many users long-haul connect into one, single processing location, has a key advantage: consolidation. When a lead-acid battery fails (which is typically in the 2.5 to 3-year range), the data center’s in-house maintenance employees replace it during their shift, making the labor costs negligible. The system also needs to be shut down during replacement – adding cost to the operation via downtime. Most Li-ion solutions are modular and are designed for hot-swap capability which means that the system can continue to operate during battery replacement. The actuality of a Li-ion battery replacement within the typical 5-year life is also rare. More advanced Li-ion BBU solutions also offer detailed communication to the system administrator – reporting state of charge (SOC), state of health (SOH), and incident reporting. This information supports preventative maintenance of the local power system.

From a comparative deployment perspective - edge systems and microdata systems have multiple nodes in various locations. In some cases, there can be hundreds of nodes in hundreds of sites, scattered across a wide region. With a lead-acid BBU system in place, failures may not be revealed until the alternative power is needed. This failure then creates the replacement effort, which kicks off a complex, multistep process. Here’s how lead-acid based BBU can add to the overall cost of maintenance.

- Incurs mileage and travel costs to reach multiple locations that can number into the hundreds, especially if they’re scattered across a wide region.

- Because the nodes are located in a locked, secure, usually unstaffed location, replacing the battery means scheduling a service call to gain access to the site.

The lithium-ion BBU solution for edge and micro-datacenter systems

When it comes to providing battery backup for edge and micro-datacenter systems, lithium-ion batteries have the advantage, because over the life of the battery, they cost less. The following is a look at the benefits of a BBU system designed by Inventus Power, compared to a lead-acid battery system:

- Expected life of Inventus Power BBU is 5-10 years, sometimes longer, which is two to three times longer than lead-acid. This could even exceed the life expectancy of the edge system.

- Li-ion is more compact, taking up 50-70% less space than lead-acid, weighing 50-60% less. Because nodes are often housed in leased facilities, this simplifies space-planning and leaves room for revenue-generating equipment.

- Rapid recharge after a backup event, up to five times faster, reducing downtime and increasing reliability.

- Optimal for off-site monitoring, because Inventus Power BBU systems offer access to battery status, including state of charge (SOC), state of health (SOH), and history of events.

- Supports wide temperature ranges, which increases reliability and performance.

- Hot swappable system eliminates the need for system downtime during maintenance.

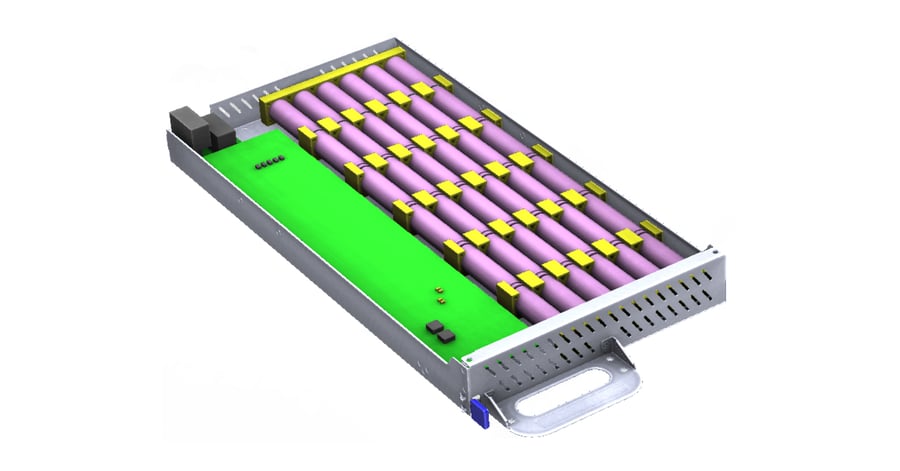

Inventus Power offers a wide variety of custom and standard Li-ion BBU solutions for hyperscale datacenter, micro-datacenter and edge applications. An example is the OCP openEDGE BBU module which offers 1.6KW of continuous output power for complete system backup for 5-7 minutes.

When weighing the pros and cons of a Li-ion BBU for edge and micro-datacenter applications, remember this: Higher cap ex (capital expenditure), but significantly lower op ex (operational expenditure). When you do the math, comparing the lifetime costs of Li-ion vs. lead-acid, Li-ion comes out ahead every time in the Edge. As a global leader in advanced battery systems, Inventus Power specializes in the design and manufacture of Li-ion power systems. Contact us today to learn more.

When weighing the pros and cons of a Li-ion BBU for edge and micro-datacenter applications, remember this: Higher cap ex (capital expenditure), but significantly lower op ex (operational expenditure). When you do the math, comparing the lifetime costs of Li-ion vs. lead-acid, Li-ion comes out ahead every time in the Edge. As a global leader in advanced battery systems, Inventus Power specializes in the design and manufacture of Li-ion power systems. Contact us today to learn more.