Welcome back to another Li-ion Battery 101 blog! This week we'll examine a crucial aspect of battery design - safety. We'll discuss the precautionary measures put in place with Lithium-ion (Li-ion) and what we do at Inventus Power to keep our batteries safe.

In recent years, the safety of Li-ion batteries has been questioned. Several notable recalls and news reports of incidents surrounding devices like cell phones and scooters have been prevalent in the media. However, often these reports do not consider how batteries can be used safely and operate without incident, even under abuse conditions. At Inventus Power, one of the key tenets for battery design and engineering is safety.

Li-ion batteries must be designed safely from the very beginning and this process includes a number of considerations. First, the application for the battery must be fully defined. An engineer must understand the operating environment, including temperature extremes. Then, we must understand the operating modes, such as how much power is drawn from the battery and how quickly it is drawn along with the duration of discharge. How quickly must the battery be expected to charge? These factors help with the initial cell selection. It is important to note that not all Li-ion cells are the same. Each cell has its own characteristics, so some cells are better suited to operate safely within certain temperature limits, operating modes, and charge limits.

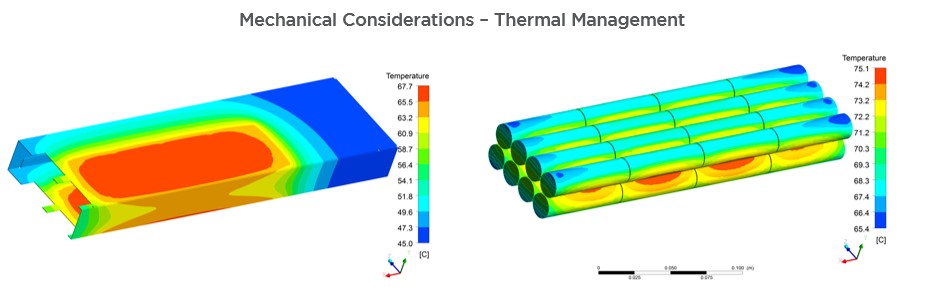

Cell selection leads into the mechanical design process, starting with the arrangement of cells inside a battery pack. There are two important factors to consider in this process. First, one must consider temperature and where the cells must remain within their specified maximum (and minimum) operating limits throughout the life of the pack. An engineer must contemplate the heat dissipated by charge or discharge of the cells during normal to extreme operation and abnormal conditions. Take, for example, a battery pack that must operate in a hot desert environment under direct sunlight. This pack must be capable of dissipating heat to an already elevated environment. Our engineers will take this into account and ensure sufficient cell spacing, thermal dissipation materials to provide passive cooling, or even include active cooling elements when necessary to prevent overheating. Thermal simulations are performed to model how the pack and cells within will perform under the different modes of operation in the customer specified environments and beyond. We will then perform qualification on actual production level battery packs, testing a multitude of extreme conditions and environments to ensure safety for every product we design.

The next concern addressed by our mechanical engineers is designing our battery packs to withstand physical damage while protecting the cells within the device. Physical damage is the most common reason for incidents surrounding Li-ion batteries. The cells must be protected from puncture, crush, and shock. The design of the pack housing is critical to ensure this damage does not occur in the event of abuse. Our engineers work closely with our customers to define the level of robustness and determine the type of testing required for each product. For example, if the product is to be handheld with a detachable battery pack, then a drop test from table height level, or hand level, is necessary. With this mode of operation defined, Inventus Power engineers ensure the housing of the pack itself is capable of surviving drops from table heights without damage to the cells within the pack.

Safety through mechanical means is the first line of defense to support battery safety, but it is not the only line of defense. Electrical and software engineers are also critical to ensuring Li-ion battery safety. In an upcoming blog, we will discuss the Battery Management Systems (BMS) in more detail, but today, I’ll discuss how the BMS helps with maintaining safety.

When designing the BMS, electrical and software engineers need to take into account the application’s operating requirements to ensure that the product functions within its limits remains safe even if the limits are exceeded. For example, if the battery has been operating beyond its thermal limits, say in an overly hot or cold environment, we will prevent the device from delivering power (output) to prevent damage to the battery. In turn, this protection from excessive temperature operation maintains the safety of the battery pack.

Another example of electrical and software protections is the prevention of electrical stress like overcharge, over-voltage, over-current, or short circuit. These electrical stresses would damage cells and even cause an incident, so our engineers take these stresses into account for all our product designs. Overcharge prevention is one of the most critical safety requirements for battery packs. Our engineers will work with customers to ensure we get the maximum capacity designed into a battery pack when charged to safe levels. If improperly charged, our battery packs are designed to prevent charging beyond a safe level (overcharge). To ensure that this safety measure is triggered, we perform testing to manually charge the pack beyond acceptable limits. The product can only be qualified for production when it passes this over-stress test.

As we've learned, Li-ion battery packs can be safely designed and developed. At Inventus Power, safety is fundamental and included in our design process from initial cell selection to the mechanical design of the housing, to the electronic protections designed within the BMS. The key is working closely with our customers to understand the application, mode of operation, and intended environment to tailor the safest solution. This is proven in our track record for providing our customers safe and reliable batteries over the past 60 years.

In our next blog, "What is a Battery Management System?" we'll take more of a systematic look into the main functions of the BMS and discuss design considerations for adding enhanced safety and intelligence features into a Li-ion battery pack.