Welcome back to Li-ion Battery 101! So far, the blogs in this series have covered a variety of topics related to Li-ion batteries at the cell level. Li-ion cells are the basic building blocks for Li-ion battery packs which can consist of one or more cells and other components. Similar to a gas tank in a car, the Li-ion cell is a stored energy source, but without the rest of the fuel system, it is not very effective. In this blog, we’ll discuss the various components that are necessary to build a functional and safe Li-ion battery pack.

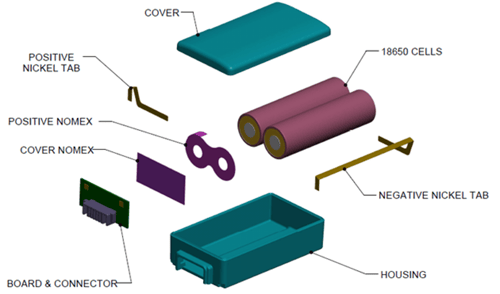

The diagram below illustrates the typical elements found in a rechargeable battery pack:

- Cells (Different form factors & chemistry types)

- BMS (Electronics to manage the battery)

- Connection System (Connector, pigtail, wires)

- Housing (Plastic, sheet metal, shrink, etc.)

Let’s take a deeper look into each of these battery pack elements.

Cells

We’ve already provided some basics about Li-ion cells in our previous blog posts, including different form factors and chemistry types. At the base of every Li-ion battery pack is the battery cell or cells. A pack can contain one cell or many cells configured to achieve higher capacity or output voltage. This is achieved by connecting cells in parallel or series, and we'll explore this much further in our next blog. The cell is considered the “fuel tank” of the battery pack system, holding the energy that will be released during discharge (when the engine is running) or replaced during a charge cycle (when the tank is refilled at a gas station). However, there are other components needed to utilize the energy stored in the cell.

BMS

To safely use the energy stored in cells, the Li-ion battery pack needs a Battery Management System (BMS). The BMS is the control system of the pack and can be simple or complex, depending on the need of the battery pack and host application. Returning to the car analogy, think of a battery pack's BMS like a car's control system. In a car, the control system shuttles fuel from the fuel tank to the engine to be utilized in a controlled and safe manner and notifies the user of any issues (i.e. low fuel). The BMS performs a similar role by safely regulating the energy carried through the cells inside a battery pack. It can also communicate information back to the end user (i.e. low battery life).

Connection System

Connection System

While we may understand the basic concept of a cell and the BMS, how do these components interact with one another? The connection system is what transforms a cell into a battery pack. There must be a connection between the cell and the BMS in order to interface with each other. Nickel strips are the preferred method of connecting a battery cell to the control system. A thin strip of nickel is capable of carrying high amounts of current, is flexible, durable, and can be attached to the cell without the use of excessive heat. These strips provide a safe means of getting the "fuel" out of the "fuel tank" to use it in a safe manner.

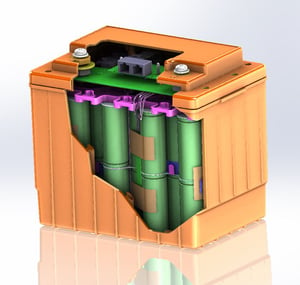

Housing

Lastly, all these components need to be packaged so that the battery pack can be installed into a device. Once all components are properly placed and connected to one another, they are sealed with either shrink wrap or a hard case. The housing ensures that the components remain safely located and provides a clean package for the eventual use by an end user. The type of housing depends on where the battery pack will be located inside the device and if it is intended to be accessed by the end-user or a technician.

Inventus Power has over 60 years of experience designing and manufacturing battery packs ranging from a simple one cell battery pack for a portable electronic device to more complex, multi-cell modular systems for motive applications. While battery packs fundamentally all share the basics: cells, BMS, connectors, and housing, the functionality and capabilities of battery packs will vary depending on the requirements of the host device and performance expectations. In our next blog, we will learn how battery packs are designed to achieve more power and/or more energy. "Battery Power vs. Energy - Connecting Cells in Parallel or Series," will cover the difference between energy - the total amount of work done, and power - how fast you can do it. Stay tuned!